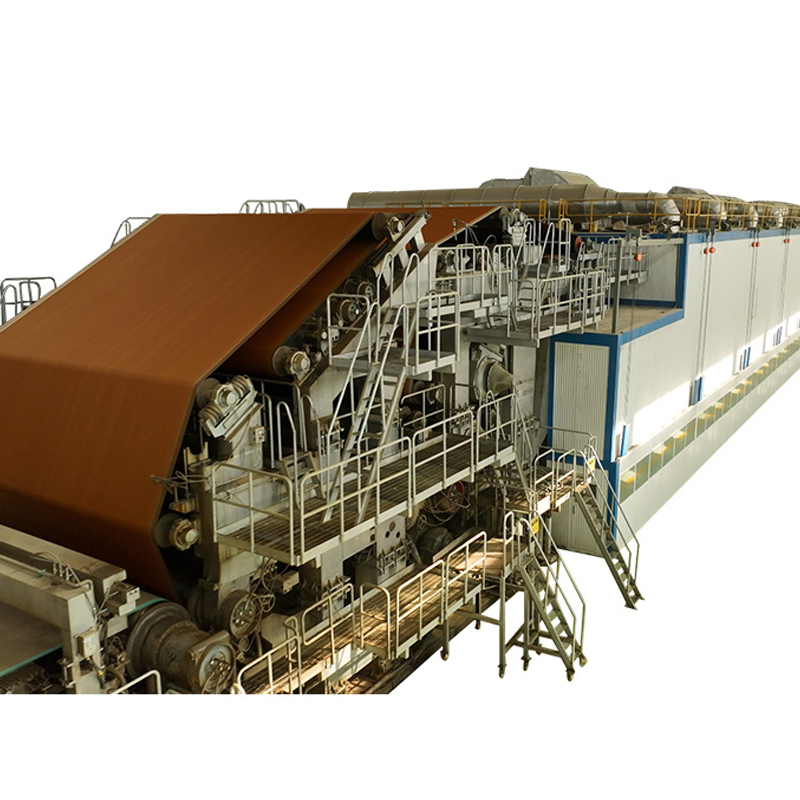

Kraft paper machines are categorized into kraft paper machines, corrugated paper machines, paperboard machines, etc. according to the type of paper produced. According to the type of paper former used, paper machines are divided into long mesh, round mesh, clip mesh and long round mesh models.

A paper machine can be viewed as a coupling machine consisting of several pieces of equipment. It is usually divided into two main parts: the wet part and the dry part. Wet section includes pulp flow equipment, net section and press section. Cadre includes the drying section, calender and winder.

1. Net section

Net is mainly used to remove the water in the pulp, it bears the vast majority of the dehydration task, in addition to a certain degree of disturbance to the pulp, while making the paper has a good molding, which consists of the top net and low net composition, the two nets are designed to make the paper in the water to the paper on both sides of the paper to take off, so as to reduce the two-sided nature of the paper.

In the design of the full consideration of the convenience of changing the net and the use of cantilever beam structure, its main components are molding board, dewatering board, vacuum case box, the upper suction box, loading table and preloading table, vacuum suction box, ambush roll, chest roll guide roll and doctor blade, drive net roll, water needle and high-pressure water spraying water and other components.

2. Press section

The press section of the paper machine is composed of several groups of roller presses. The wet paper web is drawn by the press felt and dewatered by mechanical extrusion between the press rolls. In order to maintain the good dewatering performance of the press felts, the upper rolls of the press are equipped with a felt washing device. After the press section, the dryness of the wet paper web is generally up to about 40%.

| Product | Kraft Paper Machine |

| Weight range | 100-300g/m2 |

| Trim paper width | 3900mm |

| Rolled paper width | 3950mm |

| Production capacity | 120t/d |

| Working speed | 130-200m/min |

| Design speed | 200m/min |

| Crawling speed | 25m/min |

| Wire width | 4400mm |

| Rail distance | 4900mm |

| Transmission method | AC Motor Division drive |

| Arrangement model | one layer arrangement |

| The main products | high strength corrugated paper,Kraft liner paper |

Reviews

There are no reviews yet.