- Main parameter

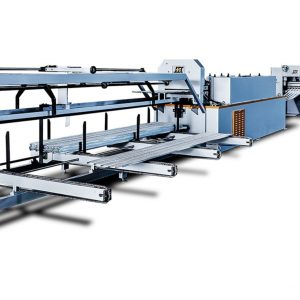

Plaster stop machine is the latest type of expanded metal mesh machines designed by our company recently. This machine features high yield, low noise, environment protection and easy operation. The required floor space of whole line is 36 square meters, and the whole line is usually 10 to 12 meters long. This production line is mainly composed of four parts: decoiler, expanded main machine, roller profiling machine, and receiving unit.

Decoiler size: 960*950*1270mm

Decoiler Weight: 400kg

Inner diameter: 470mm – 540mm

Mesh opening size: 25mm×10mm or according to customer’s requirement

Punching force: 6T

Material thickness: 0.4-0.7mm galvanized steel

Mold material: Cr12, 1 full set or according to customer’s sample

Hydraulic pressure: 5MPa

Total machine weight: about 4.5T

Layout size of the plaster stop line: 2100*9800*1700mm

Hydraulic oil type: 32# hydraulic oil

Plaster stop bead length: max. 3m

| Model | Render depth | Length | QTY/box | |

| Galvanized steel | Stainless steel | |||

| ABE-PSB1024 | – | 10mm | 2.4m | 50 |

| ABE-PSB1030 | PSB1030S | 10mm | 3.0m | |

| ABE-PSB1324 | – | 13mm | 2.4m | |

| ABE-PSB1330 | PSB1330S | 13mm | 3.0m | |

| ABE-PSB1624 | – | 16mm | 2.4m | |

| ABE-PSB1630 | PSB1630S | 16mm | 3.0m | |

| ABE-PSB1930 | PSB1930S | 19mm | 3.0m | |

Reviews

There are no reviews yet.